Start with listing your requirements

A lot of different factors have an influence on the final cost of a bioreactor, including the type of organism to be cultured, the desired working volume, the level of process monitoring and control needed, the sterilization method as well as ongoing costs (such as service or consumables). All these factors should be included in your list of requirements.

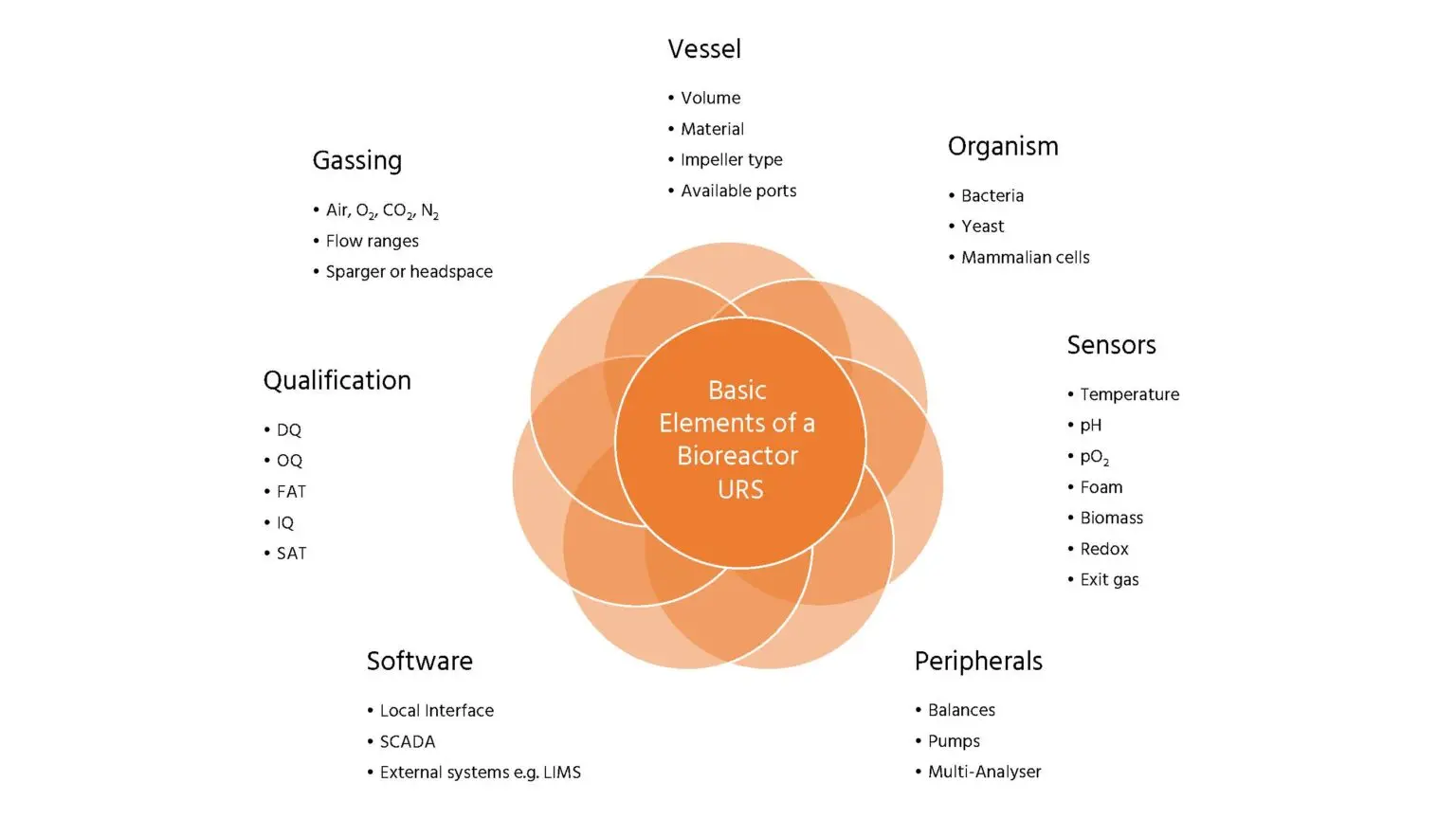

The basic elements of a URS are:

- Type of organism to be cultured

- Construction material (glass, stainless steel, single-use)

- Number and working volume of vessels

- Impeller type and speed

- Sterilization method

- Gas mix (Air, O2, CO2, N2), Gas flow, sparger and/or headspace

- Sensors (e.g. temperature, pH, pO2, foam, pCO2, biomass, redox, exit gas, light, etc.)

- Peripherals (e.g. pumps, balances, multi-analyzer)

- Local interface and Bioprocess Software

- Qualification

- Warranty, maintenance contracts and user trainings

Basic elements of a bioreactor user requirement specification. Abbreviations used: DQ – Design Qualification; OQ – Operational Qualification, FAT – Factory Acceptance Test; IQ – Installation Qualification; SAT – Site Acceptance Test.

Now have a look at each item and answer the following questions:

- Is it necessary at all?

- Is it a "must have" or "a should have" option or simply “nice to have”?

- Do I know what range of operation to specify e.g. stirrer speed of 100-1200 rpm?

- Are there choices I have to make to get what I need such as low or high speed motor, torque, top or bottom mounted?

- Is there any ambiguity that will lead to questions about what I actually need?

Compare different manufacturers

Having mentioned the creation of a URS the focus moves to what a manufacturer has to have in place to fulfill an order. Much will be the same for any company, but the different parts of a bioreactor add some specific considerations. The nature of the equipment means that a high standard of designers, document creators, engineers and quality specialists are needed to only get an item out of the factory’s door. The support from service teams and application specialists is additional to these demands.

Furthermore, you might find it important to consider how manufacturers approach to meet these needs:

- What is considered during the manufacturing process?

- What support is provided before, during and after construction?

- What can you expect in the long-term in terms of warranty service and upgrade potential?

Another vital component is the element of trust you have in the chosen supplier. This is a blend of your experiences of that supplier, their expertise and knowledge plus the value they add to your working life e.g. it’s not just about the hardware.

Consider ongoing costs

After purchasing a bioreactor, ongoing costs will be incurred. Costs must be included for recurring items over the lifetime of the equipment. These include:

- Annual service visits and any service contracts for repairs

- Renewal of any software licenses and support agreements

- Consumable and single-use items such as gas filters, tubing, and seals

- Energy and service costs, including water, air, gasses, steam, and electrical power

- Personnel training

- Insurances, regulatory licensing plus any health and safety requirements.

Be careful when comparing prices

When you start comparing prices from different manufacturers make sure you always compare apples with apples. The created list of requirements will help you keeping your focus on all essential elements. Some manufacturers try to lower the initial price by supplying minimal value. However, on the long run this will likely result in increased future costs and lower efficiency and working productivity. In general, the cost of laboratory space, infrastructure and staff exceed by far the initial acquisition costs of a bioreactor. Which in the end justifies the truth that quality matters and comes with a price.

Summary

Fortunately, most details will not directly trouble the purchaser and end user of a bioreactor. They see an end-price for a system to meet their needs. The price of such a system is not the most important factor, although budget limitations cannot be ignored. A low-cost bioreactor may be fine for undemanding, occasional use but will be a as a regular workhorse or an adaptable development platform.

The key element to focus on is the value provided in having such a system. This can be defined in several ways:

- How well it meets current requirements

- How well it matches future expectations

- How much flexibility can be incorporated for further modifications

- How will it impact an individual user to the whole organization in terms of cost saving, time saving, increased productivity and overall Return On Investment (ROI).

- How much additional benefit is provided by an ongoing relationship with the manufacturer in terms of support, information and sharing of expertise

The message is that knowing the price is a long way from knowing the value of buying a bioreactor from one manufacturer or another.