Why adjustable orbital throws matter

An incubator shaker with an adjustable orbital throw provides the flexibility to meet diverse research demands, from bacterial cultures to mammalian cells and microtiter plates. While the throw is not typically adjusted daily, it is invaluable when transitioning to new research projects that require a different approach to oxygen transfer and mixing. This capability ensures you can fine-tune your shaker to meet the specific requirements of any experiment, enhancing reproducibility and efficiency.

The science behind orbital throw and speed

Oxygen transfer efficiency is determined by the centrifugal force generated by shaking, which depends on both orbital throw and speed:

- Linear relationship with throw: Doubling the throw (e.g., from 25 mm to 50 mm) doubles the centrifugal force.

- Exponential impact of speed: Doubling the speed quadruples the centrifugal force, significantly enhancing oxygen transfer.

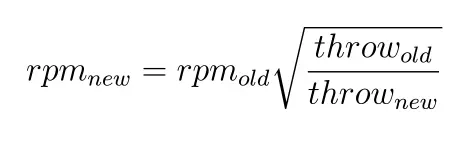

For consistent performance when changing throws, adjust the shaking speed using this formula to maintain the same centrifugal force:

e.g.,

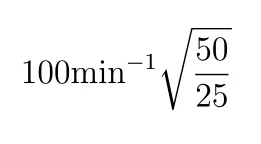

e.g.,  to calculate the speed for 25 mm shaking throw as 141.4 min-1 when transferring from 100 min-1 at 50 mm shaking throw.

to calculate the speed for 25 mm shaking throw as 141.4 min-1 when transferring from 100 min-1 at 50 mm shaking throw.

INFORS HT orbital throw options

INFORS HT offers a range of orbital throw configurations designed for diverse applications:

- 3 mm throw: Ideal for high-throughput screening using 96 deep well plates or similar formats.

- 25 mm throw: The go-to option for most standard applications.

- 50 mm throw: Optimized for large vessels and oxygen-intensive cultures.

- Adjustable throw: Available on specific models, allowing you to switch between 12.5 mm, 19 mm, 25 mm, and 50 mm throw.